Lockout Tagout

Thanks to the Lockout Tagout products from Brady and Master Lock, accidents can be prevented. Every year, thousands of workers are injured, sometimes fatally, during repair and maintenance work on installations, industrial power sources, and machines. Many of these accidents are caused by insufficient locking of the power supply. Lockout Tagout is the way to prevent energy from being released unexpectedly.

LOCKOUT TAGOUT PROCEDURE

Safety on the work floor is of priceless value. In professions where heavy electrical installations and machines are used daily, an accident or incident can quickly occur. Such an accident often has serious consequences for the employee and the company itself. It is therefore of great importance to make the workplace as safe as possible. In many cases, this can be done with Lockout Tagout safety procedures. Employees who perform maintenance or repairs on electrical machines generally run a great deal of risk. During a normal inspection, they can come into contact with high voltage, moving components or even hazardous substances. In order to prevent any incidents, certain procedures must be used. This is more than possible with Lockout Tagout, also known as LOTO.

EXECUTE LOCKOUT TAGOUT

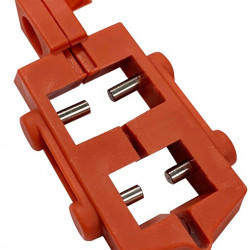

The use of Lockout Tagout is part of a safety procedure and is specifically intended to protect employees from unexpected release of energy while maintenance or repair work is being performed. Lockout Tagout safety procedures involve the use of safety padlocks, mechanical locks, electric locks and safety tagsNone

By using Lockout Tagout procedures from Brady or Masterlock reduce the chance of industrial accidents. You lock the energy source and prevent this energy from being released unexpectedly. In addition to good prevention against such industrial accidents, Lockout Tagout can save time during maintenance and cleaning of your machinery.

LOTO LEGISLATION

Due to safety and health aspects, minimum requirements have been established by the EU for employees that work equipment must comply with. These measures (European Directive 89/655/EEC) must ensure that the machines used in the company are safe for employees and cannot endanger health. This includes Lockout Tagout.

The US OSHA regulation “Hazardous Energy Under Control” (LOTO) requires employers to establish a program and use procedures to apply appropriate lockout and tagging devices to isolators and otherwise render machinery or equipment inoperative to prevent the unexpected energization, initiation or release of stored energy to prevent injury to employees. Lockout Tagout is therefore essential in an organization where hazardous machinery and equipment are frequently used.

LOCKOUT TAGOUT TOOLBOX TRAINING

Working safely with Lockout Tagout is not simply placing a tag.padlock or a safety tag. Lockout Tagout is a planned safety procedure that involves a lot. Employees need to be trained to deal with LOTO correctly and with any critical situations when they occur. As a reliable Lockout Tagout specialist, Nedelko offers a so-called toolboxtraining. During this training, work situations are discussed that have direct consequences for the health and personal safety of employees. An explanation is also given about the various Lockout Tagout products and any matters that need to be taken into account, so that machines and electrical installations can be secured before maintenance is carried out.

WORKING WITH LOCKOUT TAGOUT YOURSELF

Are you about to start a Lockout Tagout procedure, would you like more information about a LOTO toolbox training, or do you need advice, then we would be happy to visit you. Our experienced specialists know which LOTO product you can use best and most effectively. Even if you are already using our products, we would be happy to see how you can possibly improve this. Lockout Tagout products from Nedelko are quickly available, robust, easy to use and effective!